Vibration Test

- To qualify products during the product development phase, product manufacturing phase and product delivery to customer phase. Vibration testing is done by introducing a forcing function into a structure / product using a vibration test shaker.

Salt Spray Test

- Testing of a product’s susceptibility to saline-induced corrosion. Through tests such as salt-spray testing, companies can understand the extent in which their products succumb to corrosion.

Thermal Shock Test

- Thermal Shock is a mode of environment testing whereby objects are exposed to a sudden change in temperature within seconds for different periods of time and cycles.

Highly Accelerated Life Test (HALT) / Highly Accelerated Stress Screen (HASS)

- HALT and HASS are tests that subject products to a random six-degrees-of-freedom vibration and rapid thermal change rates – in the combined environment necessary to accelerate the failure of the product.

Solar Thermal Test

Temperature/Humidity Test

- Temperature/humidity testing simulates different climatic conditions. High humidity accelerates oxidation and rust in products. This increases the conductivity of permeable insulators and leads to malfunction in electronic products.

Strain Gauge & Vibration Measurement

- Testing involves mounting of accelerometer sensors on the automotive to capture real-time vibration experienced on the vehicle.

Pressure Measurement

- Calibration and measurement of up to 16,000psi and 0.9bar for vacuum calibration.

- Measuring devices employed include gauges, transducers and recorders.

Radiation Calibration (Non-accredited)

- DMC 3000

- SOR Dosimeters

Torque Measurement

- Calibration and measurement of up to 2500Nm and cable-tension meter up to 300lbf.

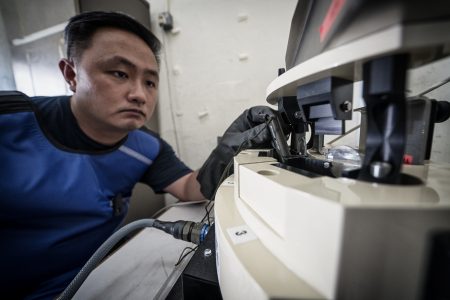

Dimension

- Calibration and verification of all types of measuring instruments and tools :

- Fixtures and jigs

- Micrometers, calipers, depth and height gauges

- Displacement sensors, dials, electrical gauge and thickness gauges

- Plug and ring gauges (thread and go-no-go gauges)

- Feeler gauges, vee blocks, engineer’s parallel/square, straight edge, film thickness gauges, test sieves, spirit level, clinometers / digital protractors, bore gauges, measuring tape, steel rule, glass scales, radius gauges, electronic comparators, and checkers

- CMM dimension measurement services

Force Measurement

- Verification of force measuring devices such as load cells, proving rings and durometers.

Mechanical Testing

- Testing of metal, polymer, rubber and composites for tensile strength, bend, shear strength, hardness (Brinell, Rockwell, Vickers, Micro-hardness), Charpy impact, compressive strength and flexural strength.

Chemical Composition Analysis

- For raw materials (metal bars / sheets) used for manufacturing / processing. Such materials need to be checked for conformance to the required specification to ensure that the products are good for their intended purposes, e.g. strength, corrosion resistance, toughness

- Our comprehensive solutions include employing Arc Spark-Optical Emission Spectrometry, Combustion, Inert Gas Fusions, and various other wet / classical methodologies.

- Analysis of bath solutions for electroplating, cleaning and etching / pickling processes are also our forte to ensure top-notch quality of our customers’ finished products.

Welding Competency Test

(CAAS SAR Chp 6.5–Appendix 1)

- For metal scaffoldings, reinforcement bars, reinforcement bars with coupler, steel wire, welded steel fabric / structures / plates / pipes

Thermal spray / Plasma coating evaluation

- Metallurgy and Failure analysis

- Failure investigation on components and equipment

- Material evaluation by metallurgical examination

- Coating thickness, grain size and ferrite measurement

- Corrosion investigation, corrosion prevention advisory services and material selection

- Macro and micro examination

- Case depth / Decarburisation depth measurement

- Inclusion / grain size checks

- Analysis / coating measurement for PCB

- SEM/EDX

IEC 62133 and IEC62620

per IEC 62133 and IEC62620

ISO 9001

OHSAS 18001 / ISO 45001

ISO 14001